A large volume of wastewater generates a significant cost

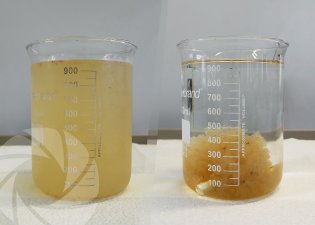

Our client has several equipment for the production of its beverages that require CIP and COP cleaning. These operations generate nearly 10,000 liters of wastewater daily. The wastewater is first stored and then disposed of by an external waste treatment company. The costs for treatment and disposal amount to several thousand euros per year. NISKAE is able to offer a solution adapted to the needs of our Client which will allow on the one hand an important reduction of the costs and on the other hand the setting in conformity of the discharges of the factory to the sewage systems.