The production process requires the application of paint using spray guns. These should be cleaned with clean water regularly as soon as a colour change is necessary. Tools used for colour preparation as well as containers and storage tanks are washed daily. Consequently, the rinsing and cleaning water are found to be polluted with paint residues in varying amounts. The volumes of wastewater average 1,500 liters per day. So far, the solution used has been a settling process, but the water cannot be reused and the company is forced to store and dispose of the wastewater by a waste treatment provider.

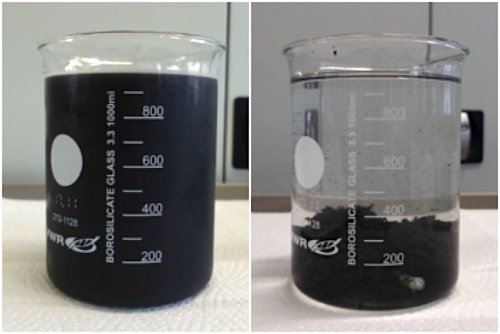

NISKAE offers full support for the initial sampling in order to carry out a series of laboratory tests and analyzes and thus develop a specifically adapted coagulant-flocculant formulation. The company sent two samples of process water loaded with paint and their analysis revealed a strong contamination by heavy metals (nickel at 5.3 mg/L, phosphorus at 6.5 mg/L and zinc at 2.5 mg/L). After several series of tests, NISKAE was able to offer an effective coagulant-flocculant with minimum dosage - only 1.5 g/L. Following encouraging results, particularly in terms of clarification, suspended matter content (SS) or even pH value, the company now considers recycling treated water to reuse as cleaning water.

A tailor-made coagulation-flocculation solution enables the treatment of washwater in a simple, fast and efficient manner. Storage and logistics operations are greatly simplified for the customer. A more responsible management of wastewater and a considerable reduction in operating costs. The proposed treatment, associated with a SW microstation supplied by NISKAE, allows the company to have a compact, flexible and fully adaptable process