The SW100 station, easy to use and maintain, overcomes contaminated wash water

The company, concerned about its image, wants to quickly find a solution for the responsible management of wastewater. After careful analysis of water and daily flows, qualified NISKAE professionals propose an efficient and sustainable personalized plan.

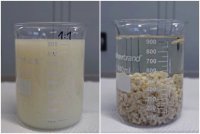

NISKAE installs a SW100 station, suitable for flows up to 100 L/h. Factory managers immediately appreciate its simplicity! The operation of the station is based on physicochemical water treatment and the addition of a coagulant-flocculant reagent;

- Dirty water flowing from washing stations is collected by gravity in a well;

- Thanks to a level detection, waters are then pumped to a 500 L storage tank equipped with a stirrer to ensure homogeneous mixing and avoid any decantation effect;

- From the tank, using a specifically developed coagulant and flocculant, the station treats 100L of water, each filling;

- The discharge of clean and clear waters is done directly into the pipeline, to the natural environment.

The company now has a simple and efficient wastewater treatment system: a responsible investment that abolishes the cost of storing and transporting polluted materials! A very suitable plan for this ECOCERT certified SME.