Our customer washes its coating machines several times a day, generating a daily wastewater volume of approximately 15,000 liters of wastewater containing mainly varnish residues, TSS, BOD and COD. Within the framework of its operating permit, our customer must treat its wastewater with the main criterion of correction: the COD (Chemical Oxygen Demand). The level of COD must be lower than 800 mg/L. In order to secure this discharge, NISKAE proposes a coagulation-flocculation process.

The NISKAE team carried out a complete study for the different effluents of the workshop generated by the three main stages of the process. For this purpose, several samples were taken and tested in our laboratory following several protocols of dosage and adjustment of parameters such as temperature, pH or conductivity

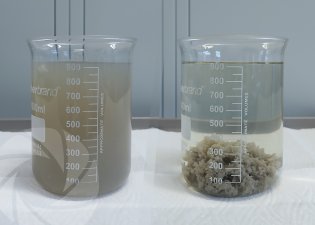

The physico-chemical treatment solution proposed for the global discharge of the industrial site requires the dosage of 2 g/L of a unique coagulant-flocculant product allowing the lowering of the COD, the reduction of heavy metals and the clarification of the washing water. The COD level was lowered to 142 mg/L and will allow our Client to ensure compliance with the discharge parameters at all times. This result has been achieved by the fact that the COD reductions obtained on the different samples are from 30 to 50%.

As for heavy metals, the specific formulation developed by the NISKAE laboratory allowed to reduce iron concentrations from 0.27 mg/L to 0.02 mg/L and zinc from 0.10 mg/L to 0.03 mg/L.